Routine

Operations Management with a focus of People, Process and Property

We believe in people. We have learned everyone wants to do a good job; however, in many cases, the definition of a good job is not known or people have not been trained to that standard, specially in manufacturing. That’s why we built Routine.

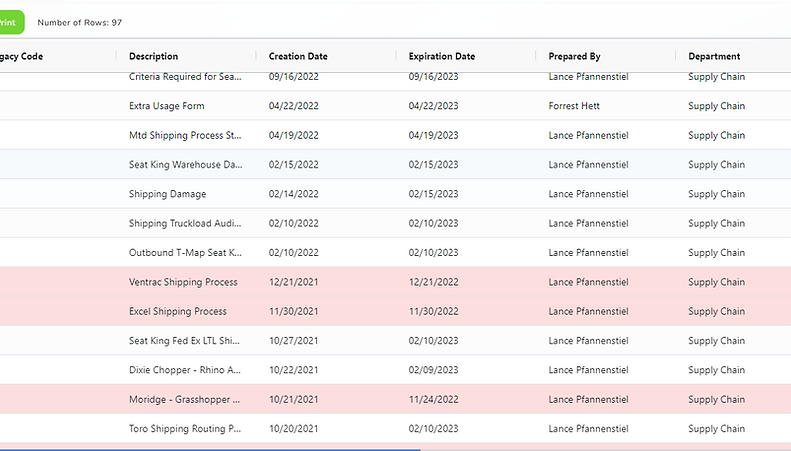

Maintaining document integrity is critical to your business. Routine, from Optegrity, puts the tools in your team’s hands to manage all of your documentation from critical audit procedures to standard work documentation.

Maintain Integrity

Track documents from inception to publication to revision and beyond.

Keep in accord with quality management systems like ISO 9001, AS9100 and IATF 16949.

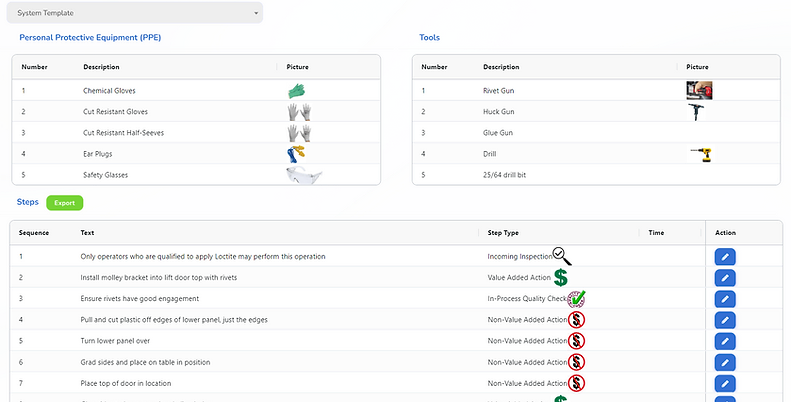

Tie Operation to safety, quality, people and assets

Training management module tied to operations to keep work instruction and organizational knowledge current

Real Time Translation to 18 different Languages

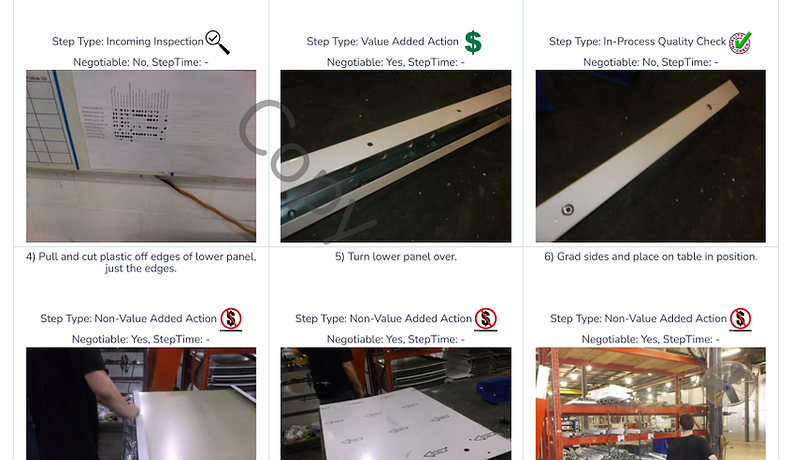

Execution Simplified

Standard work and visual instructions, now extended with real-time production visibility

Embedded MES functionality that connects people, process, and production—without replacing your ERP

A practical, point-of-use MES layer designed around how work actually happens on the shop floor

Built-In MES Capabilities

ROUTINE™ already gives you standardized work, visual instructions, and real

accountability at the point of use. Adding MES extends that foundation into realtime production visibility without replacing your ERP or over-engineering the shop

floor.

This is not a full-blown, plant-wide MES overhaul. It is a practical layer that connects people, process, and production data where work actually happens. ROUTINE™ includes embedded Manufacturing Execution System (MES) functionality designed around how work is actually performed on the shop floor.

| MES Capability | Routine (Built-In) | Traditional Standalone MES |

|---|---|---|

| Standardized Work Execution | Yes. Visual, step-by-step work instructions drive execution | Often separate from execution or require heavy configuration |

| Cycle Time Tracking | Yes. Actual vs planned capture through execution | Yes |

| Production Visibilty | Yes. Live view of what is running and where flow stops | Yes |

| Work Order Execution | Yes. Execution-level tracking (not planning) | Yes |

| Quality Checks at Execution | Limited. Supports execution checks tied to work steps | Often extensive SPC and Quality modules |

| ERP Replacement | No. Complements ERP | Sometimes positioned as a partial replacement |

| Implementation Complexity | Low. Embedded in existing workflows | High. Often multi-month projects |

| IT Overhead | Minimal | Significant |